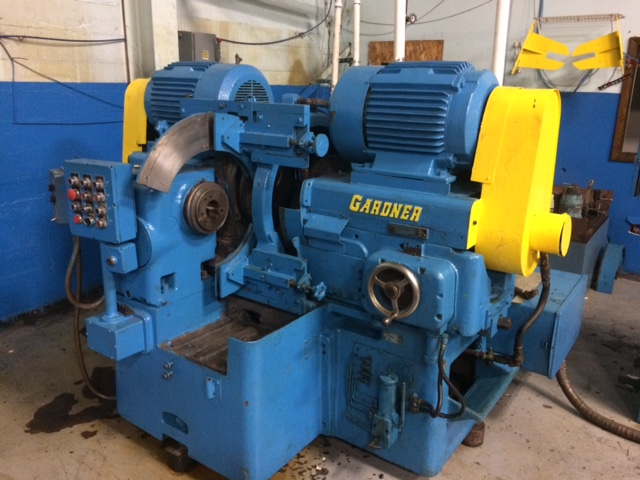

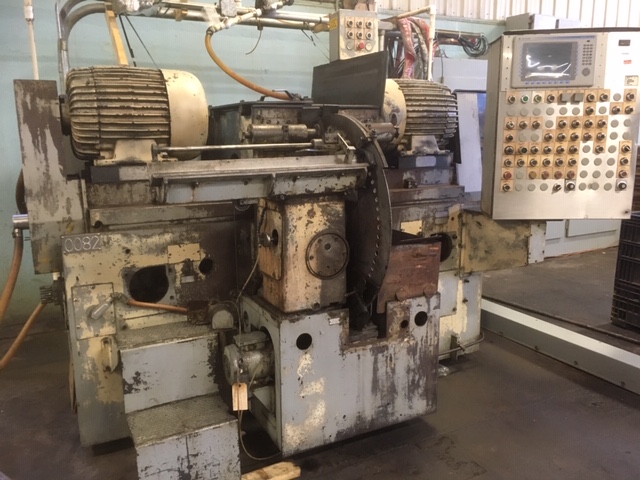

Gardner 2H20-23 Horz. Opposed Double Disc Grinder

Hydraulic Gun Feed Fixture

Serial Number: 425-2

SPECIFICATIONS:

23″ Diameter Wheels

20HP Drives

Hydraulic Gun Feed Fixture

Automatic Face Cut on 1 Head

Hydraulic Dresser

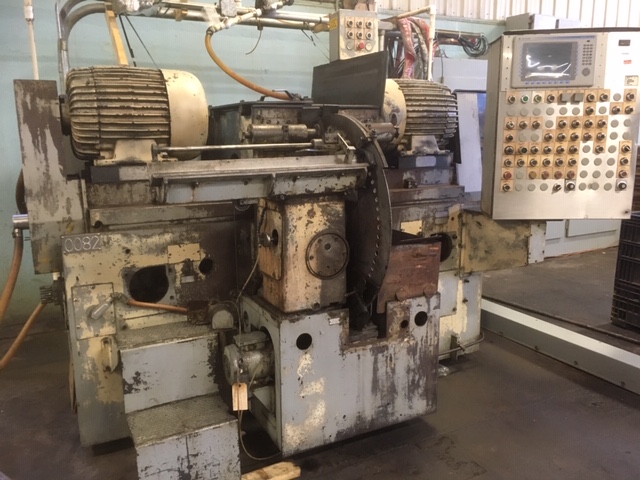

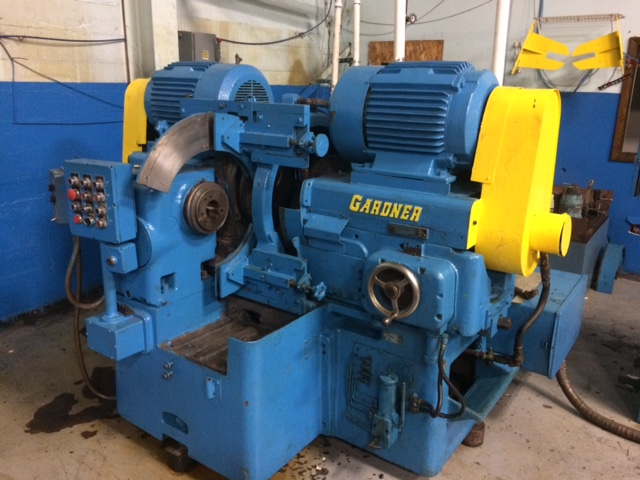

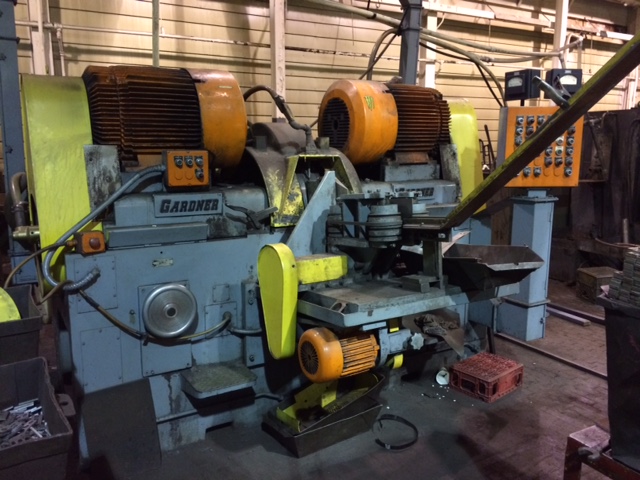

Gardner SDG2-23 Horz. Opposed Double Disc Grinder

Automatic Gun Feed Fixture

Serial Number: 89330

SPECIFICATIONS:

23″ Diameter Wheels x 3″ Thickness

12 1/8″ Max Opening between Steel Backing Plates

20HP Drives

Automatic Gun Feed Fixture

Automatic Face Cyr on Both Heads

Automatic Dresser

Auto Compensation

Free Standing Electrical Panel

Filtration System

Currently New Diamond Wheels on the Machine

Gardner SDG3-30 Horizontal Opposed Disc Grinder

Model: SDG3-30

New – 1989

Rebuilt & Retrofit (Knapp Engineering) – 1998

Serial No. 900-32

SPECIFICATIONS:

Abrasive Wheel OD: 30″ / 762 mm

Abrasive Thickness (Usable): 3″ / 76 mm

Opening between Wheels – Maximum: 15″ / 381 mm

Wheel Mounting Flange OD x Thickness: 17″ / 432 mm x 1-1/2″ / 38.1 mm

Spindle Drive Motors (2): 40 HP/3 Ph/60 Cycle/460 Volt

EQUIPPED WITH:

Rotary Work Carrier (Variable Speed)

Rockwell RS Logix 5000 PLC (Ladder Logic, System Software, Operating Disks)

Allen Bradley Panelview Plus 1000 Operator Interface with Ethernet Connection

Allen Bradley 1336 Plus Sensorless Vector Drive (Adjustable Frequency Drive)

Programmable Wheel Dresser (Automatic Dressing)

Trabon Automatic Lubrication System

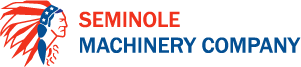

Gardner 2H20-23 Horizontal Opposed Disc Grinder

23″ Grinding Wheels

Rotary Carrier

20 HP Main Spindle Drive Motors

Thru Spindle Coolant

Central Coolant System

Free Standing Electrical Panel

Gardner SDG2-23 Horizontal Opposed Double Disc Grinder

23″ Wheels

20 HP Main Drive Spindle Motors

30″ Rotary Carrier w/ spacer

DC2 VS Drive For Carrier

Coolant in base w Central Tank

Trabon Lube System

Free Standing Electrical

440 v

Thru Spindle Coolant

2 Axis DRO

GardnerSDG5-30 Horizontal Opposed Double Disc Grinder Thru – Feed

Serial Number: 629-9

SPECIFICATIONS:

30″ Wheels x 3″ Thickness

15″ Max Opening Between Backing Plates

Belt Type Thru-Feed 66 to 400 RPM

100 HP Spindle Drives

Rapid Feeds on Both Heads

Incremental Feeds on Both Heads – 0.0001″

Thru Spindle Coolant

Spindle Lube & Grease Alerts

Spindle Load Meters

Motorized Dresser

Free Standing Electrical

Coolant Pump On Machine

Machine Dimensions: 126 3/4″ (L-R) x 90 1/2″ (F-B) w/o Electrical Panel

Machine Weight Approx: 23,500 LBS.

Machine is Currently In Plant Under Power

Gardner 2H20-23 Horizontal Double Opposed Disc Grinder

SN: 403-5

15HP Spindle Motors

23″ Wheels

240 Volt

Roller Type Thru Feed Fixture

Dresser

Free Standing Control Panel

Free Standing Electrical

Coolant Thru Spindles no Pump or Ext. Tank

Machine Completely Re-Conditioned in 2006

Gardner SDG5-30 Thru-Feed

Serial Number: 690-1

Specifications:

40HP Spindle Drive Motors

30″ Grinding Wheels

Dresser

Danfoss VLT 5000 FLUX Servo Dives for Feed on Both Heads

Allen Bradley Micro Logix 1500

Allen Bradley Panel View 550 Control

Automation Direct GS2 Drive for Thru-Feed Fixture Speed Control

3 Tier Coolant tank w/ pump

Free standing electrical 460/3/60

Gardner Opposed Double Disc Grinder 2H30 – Thru Feed Fixture

Encyclon model 654-300DT (300 gallon, dual tank) cyclonic coolant filtration system (bought new 11/13)

This Grinder rebuild was completed in 2013 to grind clutch disks. The job went away and the machine since rebuild has about 100 hours on the grinder and coolant filter. This machine is a 30″ wheel thru feed style with a caterpillar feeder unit for the fastest production rates of any double disc grinder. All new electronics. Soft starter for main spindles. PLC controlled. Stepper drives on the feed slides. Servo drives for dresser and caterpillar feeder. Digital slide readouts with glass scales. Old pneumatic slide movements were replaced with stepper drives that are fully programmable with multi step feeds. All new heavy duty dresser shaft and bearings with servo drive speed control electrics. Wheel spindles and carriers completely rebuilt. Machine will come with feed rail, the exit feed ramp, several spare sets of thru feed guides, several sets of wheels (one brand new in the packaging) one extra set of wheel back plates and all of the original parts that the machine came with from the factory.

(1) Used Gardner SDG5-30 Horizontal Opposed Double Disc Grinder

Specifications:

30″ Diameter Grinding Wheels

40HP Spindle Drive Motors

15″ Max Opening Between Wheels

6″ Max Work Capacity Thickness

0.0001″ or 0.000050″ Feed Increments

Equipped With:

Chain Hold Down Rotary Feed Fixture

Additional Carrier

(1) Set of Spare Backing Plates

(2) Full Sets of MRC Spindle Bearings ( New in Box )

460 Volt

Out of Running Service from Caterpillar